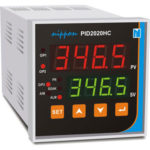

NIPPON-PID Controler 2048

nippon's PID Contollers introduces state of art, truly universal, powerful PID controller with in-house design. The PID series is developed with state of art

microcontroller.

The robust hardware and software makes the controller very useful in noisy industrial environment. The PID finds applications in Industrial Ovens, Muffle Furnaces, B.O.D. Incubators, Humidity Chambers, Environmental Chambers, Sterilizers, Blood Bank Equipments, Constant Temperature Baths, Packaging, Plastic Moulding, Thyristors Heat Controllers, Motor Controllers, Controlled Melting, Valve Control…etc.

- Universal Input

- PID Control

- Profiler

- MODBUS enabled

- Specifications

Table A:

| INPUT | SENSOR | RANGE | ACCURACY |

|---|---|---|---|

| R.T.D. | PT-100 | -200 to 600 °C | ± 1 °C |

| PT-1000 | 0 to 500 °C | ± 1 °C | |

| THERMOCOUPLES | Chromel/Alumel (K) | 0 to 1300 °C | ± 1 °C |

| Iron - Constantan (J) | 0 to 750 °C | ± 1 °C | |

| Copper-Constantan (T) | -200 to 350 °C | ± 1 °C | |

| Pt / Rh (R or S) | 0 to 1700°C | ± 1 °C | |

| D.C. LINEAR INPUTS | 4 to 20 mA / 0 to 20 mA | User Programmable | ± Least count |

| ± 50 mV, ± 100 mV, ± 200 mV, ± 250 mV | User Programmable | ± Least count | |

| ± 1V, ± 3.3V, ± 5V, ± 10V | User Programmable | ± Least count |

Specification :

| Input | ONE UNIVERSAL Input Thermocouples : J,K,T,R,S RTD's : PT-100, PT-1000 DC mA : 0 – 20 mA, 4 – 20 mA (Maximum 12 Volts) DC mV : ± 50 mV, ± 100 mV, ± 200 mV, ± 250 mV DC Volts : ± 1V, ± 3.3V, ± 5V, ± 10V |

|---|---|

| Range | Refer 'table A'' |

| Ambient | Compensation automatic, ambient 0-60 °C |

| Resolution | 1 or 0.1 or .01 or .001 programmable |

| Display | Super bright in 4 + 4 format , with NO BLINK programming technique

|

| Ananciation L.E.D's | 7 L.E.D.'s , 3 mm , multi colour, 3 for O/P's, 1 each for A/M, Alarm, Profile, Soak Time |

| Parameter Setting | By soft touch, Elegant, Sturdy membrane keys & User friendly menu driven software |

| Outputs | THREE, Programmable outputs with modular attachments

|

| Note |

|

| INPUT Control Outputs Rating | Relay SPST 230V / 3 Amp, 12 volts DC pulses for , 4-20 mA (Load 450 ohms) | ||

|---|---|---|---|

| CONTROLS | |||

|

PID / On-OFF / TP

|

||

|

|

||

|

Heat / Cool / Heat-Cool | ||

|

Provided | ||

|

|

||

|

Provided, 0 to 100% | ||

| ALARMS | Assigned for O/P2 and O/P3 Alarm Types : Low / High /Band /Deviation / End of Profile Alarm Acknowledge : Latchable / Unlatchable Alarm Inhibit : Available | ||

| Retransmission | 4-20 mA or 20-4 mA or 0-20 mA or 20-0 mA programmable, Non-isolated, Retransmission assign for O/P 2 and O/P 3 Provided on request | ||

| Communication | RS485, 2-Wire, Half duplex RS485 MODBUS on request, MODBUS RTU or ASCII Baud Rate Programmable 1200/2400/4800/9600, contact factory for higher Baud Rates | ||

| PROFILER | 2 Profile Programmes / 8 Segments Each

|

+91 9769480381 / +91 9820002155

+91 9769480381 / +91 9820002155